When constructing long-lasting, high-performance concrete pavements, whether for highways, airports, industrial yards, or municipal roads, one component plays a crucial role in ensuring structural integrity- the dowel bar. Although often overlooked, dowel bars are critically essential as they serve as the backbone for load transfer between concrete slabs, directly affecting a pavements lifespan, maintenance costs, and safety. Today, glass Glass fiber-reinforced polymer (GFRP) dowel bars are setting new industry benchmarks as a non-corrodible and maintenance-free alternative that not only enhances the performance of jointed plain-concrete pavement (JPCP) but also has the potential to reduce life-cycle costs, particularly in harsh environmental conditions. This guide explores the compelling advantages of GFRP dowel bars, making them the optimal choice for your upcoming pavement project.

The Indispensable Role of Dowel Bars in Concrete Pavements

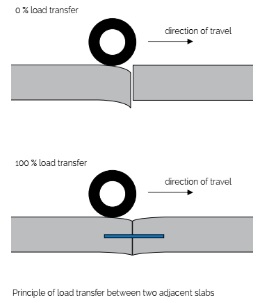

Concrete pavements are generally constructed as discrete slabs,allowing them to expand and contract in response to temperature fluctuations and moisture changes. The slab joints in concrete structures present a critical structural challenge to ensure structural integrity. Heavy loads, such as those from trucks and aircraft, must be distributed evenly across the joints. This is essential to prevent uneven stress, slab cracking, or joint faulting, which can occur when one slab moves relative to another, potentially creating dangerous conditions.

Dowel bars are particularly effective in enhancing structural integrity. Installed horizontally across slab joints, they function similarly to horizontal reinforcement bars, providing increased strength, and stability,and preventing the formation of cracks. Dowel bars function as load - transfer bridges, transferring up to 90% of wheel loads from a loaded slab to the adjacent unloaded one, ensuring uniform stress distribution and structural integrity.

Dowel bars are particularly effective in enhancing structural integrity. Installed horizontally across slab joints, they function similarly to horizontal reinforcement bars, providing increased strength, and stability,and preventing the formation of cracks. Dowel bars function as load - transfer bridges, transferring up to 90% of wheel loads from a loaded slab to the adjacent unloaded one, ensuring uniform stress distribution and structural integrity.

Without effective dowel bars, joints are prone to premature failure. Slabs may crack at the edges, joints may widen, and the pavement may develop potholes or uneven surfaces, resulting in costly repairs, a shortened pavement lifespan, and increased safety hazards for vehicles and pedestrians.

In short, dowel bars are not optional add-ons. Effective dowel bars, as a foundational component, are directly correlated with a pavements ability to endure heavy traffic, severe weather conditions, and long- term deterioration.

Why is corrosion of steel dowel bars one of the main reasons of pavements concrete premature failure?

Corrosion of steel dowels in the contraction joints of the JPCP is characterized as one of the  main reasons of premature concrete failure. The penetration of chloride containing deicing salts through the joint initiate the corrosion. Since the smooth dowel bars are assumed to be frictionless and permit free relative movement of slabs due to temperature changes, the corrosion of steel dowel bar creates exfoliation of steel surface causing steel dowels to lock in the joint. Locking in turn, causes excessive tensile loads on the surrounding concrete with attendant stress concentration on the concrete and greater movement around the joint which hasten the rate of joint failure . Furthermore, corrosion of steel dowels may restrain the free movement under temperature variations. The restriction of free movement of the concrete slabs over the dowel bars produces high tensile stresses, which in turn result in mid-slab cracking

main reasons of premature concrete failure. The penetration of chloride containing deicing salts through the joint initiate the corrosion. Since the smooth dowel bars are assumed to be frictionless and permit free relative movement of slabs due to temperature changes, the corrosion of steel dowel bar creates exfoliation of steel surface causing steel dowels to lock in the joint. Locking in turn, causes excessive tensile loads on the surrounding concrete with attendant stress concentration on the concrete and greater movement around the joint which hasten the rate of joint failure . Furthermore, corrosion of steel dowels may restrain the free movement under temperature variations. The restriction of free movement of the concrete slabs over the dowel bars produces high tensile stresses, which in turn result in mid-slab cracking

A common method that has been employed for more durable dowels was the fusion-bonded epoxy coating of steel dowels. Unfortunately, the epoxy-coated steel dowels demonstrated the same performance problems that are normally associated with surface coating including voids and damage during transportation and handling. The concentrated corrosive mechanisms at the defected area, in some cases, lead to more rapid failure than same steel-reinforcement without any epoxy coating.

Why GFRP Dowel Bars Outperform Traditional Steel Dowels?

For decades, steel dowel bars were the industry standard. However, steel’s inherent limitations—corrosion, weight, and magnetic interference—have made it a less-than-ideal solution for modern pavement projects. Engineered from high-strength materials, GFRP dowel bars are designed to withstand significant loads and stresses, as evidenced by their robust mechanical properties and performance in various structural applications. glass fibers embedded within a polymer resin matrix effectively address these issues while providing superior performance. Here’s how:

1. Exceptional Corrosion Resistance: Longevity in Harsh Environments

Steel dowels are highly prone to corrosion when exposed to moisture, deicing salts (which are prevalent in cold climates), and industrial chemicals (found in ports, factories, or waste management facilities). Corrosion causes steel to rust, expand, and deteriorate, ultimately resulting in “spalling” (flaking of the concrete around the dowel) and joint failure.

In contrast, GFRP is chemically inert and corrosion - resistant. It maintains its structural integrity in saltwater, acidic soils, and chemical - rich environments, preventing spalling and extending the pavement lifespan by 2 - 3 times compared to steel dowels.

Glass fiber reinforced polymer (GFRP) dowels are non-corrodible and maintenance-free, offering a cost-effective solution for jointed plain concrete pavement (JPCP), particularly in challenging environmental conditions. Consequently, using GFRP dowels in the JPCP as an alternative to the commonly used epoxy - coated ones will eliminate the risk of corrosion and extend the service life of concrete pavements.

2. Lightweight : Easier Installation, Lower Labor Costs

Glass Fiber Reinforced Polymer (GFRP) dowel bars are well - known to be significantly lighter than steel dowels, with a weight reduction of approximately 75% for bars of the same diameter. One meter GFRP dowel with 25mm diameter weighs only 1kg, compared to 3.85kgs of steel. The lightweight advantage brings tangible benefits to the project: streamlined transportation, which reduces fuel costs; simplified on-site operations, eliminating the need for heavy lifting in small-to-medium installations; and faster installation. The construction team installs GFRP pins up to 50% faster than steel, effectively lowering labor costs and accelerating project timelines。

3. High Strength: Uncompromised Load-Bearing Capacity

Despite their light weight, GFRP dowel bars boast an impressive tensile strength—up to 800 MPa, exceeding that of mild steel (350 MPa). Their flexural strength and stiffness are tailored to match concrete’s properties, ensuring optimal load transfer without overloading the slab. Independent testing has verified that GFRP dowels adhere to or surpass the load transfer efficiency standards set by AASHTO,DOT,EN and ASTM, making them suitable for heavy-duty applications like interstate highways and airport runways.

4. Non-Magnetic and Non-Conductive: Ideal for Specialized Projects

Steel dowels can interfere with magnetic fields and conduct electricity, rendering them incompatible with projects such as airport taxiways (where magnetic interference disrupts navigation systems), hospitals (near MRI machines), and electrical substations. GFRP, being non-magnetic and non-conductive, effectively eliminates issues related to magnetic interference and electrical conductivity.Moreover, It’s radio-transparent, which makes it well - suited for projects that require ground - penetrating radar (GPR) inspections for pavement maintenance.

5. Maintenance Free: Low Total Cost of Ownership (TCO)

Although GFRP dowels may have a slightly higher initial cost compared to steel, their corrosion resistance and long lifespan lead to significantly lower maintenance costs over time. Roads equipped with steel dowels often necessitate expensive repairs, such as joint resurfacing or slab replacement, typically within ten to fifteen years. In contrast, pavements utilizing Glass Fiber Reinforced Polymer (GFRP) dowels can sustain for 40-50 years with significantly less maintenance. When factoring in labor, In terms of materials and downtime, GFRP dowels offer a 60% lower Total Cost of Ownership (TCO) over the pavement’s lifespan.

Typical Applications of Pulwell GFRP Dowel Bars

Pulwell GFRP dowel bars are highly versatile and suitable for a broad range of concrete pavement projects, including:

• Highways and Roads: This includes interstate highways, state roads, and county roads, particularly in regions that experience frequent deicing salt use or high rainfall.

• Airports: This encompasses runways, taxiways, and aprons, where non-magnetic properties and high load capacity are of critical importance.

• Industrial and Commercial Pavements: Such as warehouse floors, manufacturing plants, port yards, and distribution centers, which are resistant to chemicals and heavy equipment loads.

• Municipal Projects: For instance, sidewalks, bike lanes, parking lots, and public plazas, which can reduce maintenance burdens for local governments.

• Coastal and Marine Environments: Roads, Streets, and port pavements—where innovative materials like GFRP demonstrates resistance to saltwater corrosion.

Frequently Asked Questions (FAQ) About Pulwell GFRP Dowel Bars

Q1: Can GFRP dowels be installed using the same methods as steel dowels, and do they require special tools?

A1: Yes, GFRP dowels integrate seamlessly with standard concrete pavement installation practices. They can be placed using dowel baskets (the most common method for new construction), epoxy bonding (for repairs), or mechanical anchoring, and no specialized equipment is needed. Their lightweight design (75% lighter than steel) simplifies on - site handling: crew members can manually place them without heavy lifting gear, speeding up the installation by 50%.

Q2: Are GFRP dowels suitable for all concrete pavement environments, including extreme climates or coastal areas?

A2: GFRP has excellent thermal stability, maintaining its strength and stiffness in temperatures ranging from -60°C (-80°F) to 80°C (176°F)—far exceeding the temperature ranges of most pavement environments. Unlike steel, GFRP material does not expand or contract significantly with temperature changes, thereby reducing stress on concrete joints.

GFRP dowels perform excellently in harsh environments where steel fails. Their chemical inertness makes them impervious to corrosion from deicing salts (in cold climates), saltwater (in coastal ports), and industrial chemicals (on manufacturing floors). In coastal highway projects, GFRP dowels have shown zero corrosion after 10+ years of service, while adjacent steel dowel installations required full replacement due to rust - related spalling. They are also non - magnetic, making them ideal for airport runways where steel interferes with navigation systems.

Q3: How do GFRP dowel bars compare to traditional steel dowels in load - transfer performance?

A3: GFRP dowels, as demonstrated by field tests and applications of many projects in the last 40 years, match or surpass steel dowels in load-transfer efficiency and exhibit superior fatigue life, while also eliminating the flaws associated with steel. GFRP dowels match or surpass steel dowels in load - transfer efficiency while eliminating the flaws of steel. Field tests and numerical simulations confirm that GFRP dowels maintain a load - transfer efficiency of 85–90%, which is identical to that of steel. Their tensile strength (up to 800 MPa) exceeds that of mild steel (350 MPa), and their stiffness is engineered to complement the properties of concrete, preventing both under - and over - loading of slab joints. Unlike steel, the non - corrosive nature of GFRP ensures that this performance remains consistent for 50 years, whereas steel dowels degrade in 10–15 years (especially in salt - exposed areas), reducing the load - transfer capacity by 50% or more over time.

Q4: Can GFRP dowels be cut or customized on-site?

A4: Absolutely. GFRP dowels can be easily cut to the required length using standard carbide-tipped saws, which are commonly found on construction sites, thus allowing for on-the-fly adjustments to match project requirements.

Q5: Do GFRP dowels meet industry standards?

A5: Our GFRP dowel bars are manufactured to meet or exceed global standards, including ACPA M254, ASTM D8444, ACI325 and EN 13877-3 . Third-party testing confirms their compliance with highway, airport, and industrial specifications by evaluating their load transfer capabilities, resistance to corrosion, and structural integrity, as demonstrated by studies on GFRP bars under alkaline conditions and constant load.

Q5: Are GFRP dowels environmentally friendly?

A5: Yes. GFRP is a sustainable material: it requires less energy to produce than steel, thereby reducing carbon emissions; it is maintenance-free and effectively eliminates the environmental impact of steel corrosion, such as rust runoff into soil or water. Moreover, its long lifespan significantly reduces the need for frequent pavement reconstruction or repair, further providing the long-term savings over time on raw materials, transportation and energy and minimizing the environmental footprint.

Choose Pulwell GFRP Dowel Bars for Long-Lasting Pavements

Whether constructing a heavy-duty highway, a corrosion-prone coastal roads, a industrial floor or a low-maintenance municipal street or parking lot, Pulwell GFRP dowel bars can provide the strength, durability, and cost savings that modern pavement projects demand. By eliminating corrosion, reducing installation time, and lowering long-term maintenance costs, they are not just a material choice—they are an investment in the durability and performance of your pavement.

The use of Pulwell GFRP Dowel Bars promotes sustainable development in global infrastructure by cutting life-cycle costs and minimizing environmental impact.

Get in touch with our team today to to learn more about our GFRP dowel bar specifications, customized solutions, and how we can support your upcoming project.

Tags :

GFRP (fiberglass reinforced polymer) dowel bars for concrete pavement, which are corrosion-resistant, lightweight, and non-magnetic, come in different sizes as well as round or square shape. When comparing steel and GFRP dowels, high-strength GFRP dowels have their own advantages. Airport paving dowels, highway,road, street dowel bars, and industrial floor dowel bars are applied in different scenarios.

No.20 Lianhong Road, Torch High-Tech Industrial Zone, Zhongshan City, Guangdong 528437, PRC

Copyright © 2025 Pulwell Composites Co.,Ltd. All rights Reserved

Tel:+86-760-86133399, Fax:+86-760-86133398